1. Compress the Slab in Two Directions with a Rib

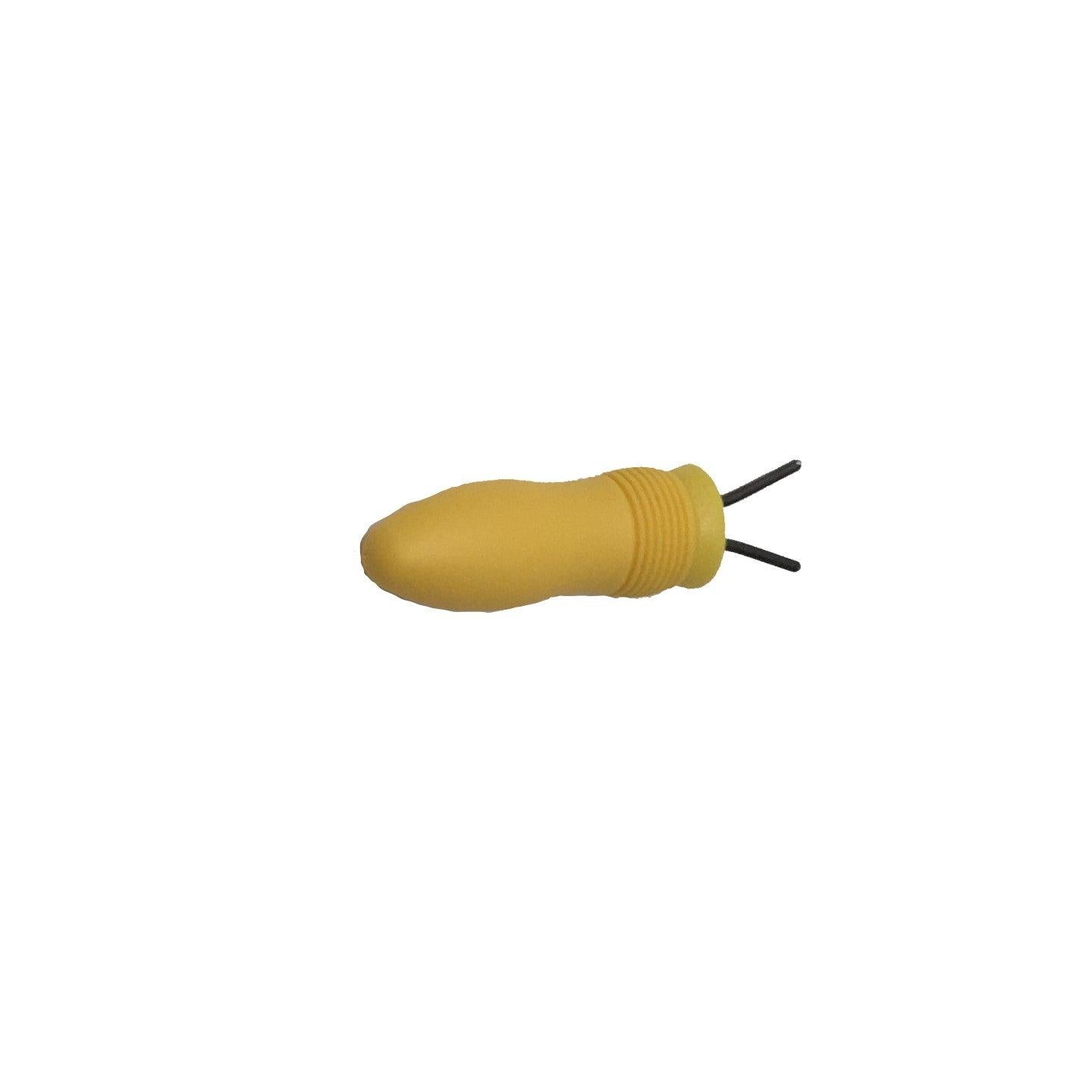

Start by preparing your slab of clay, rolling it out evenly to your desired thickness. Once it’s flattened, use a Mudtools Yellow #5 Rib to compress the slab in two directions. This helps eliminate air pockets, ensures even thickness, and sets the stage for a smooth, stable piece. This step is crucial to avoid any cracks or warping later on.

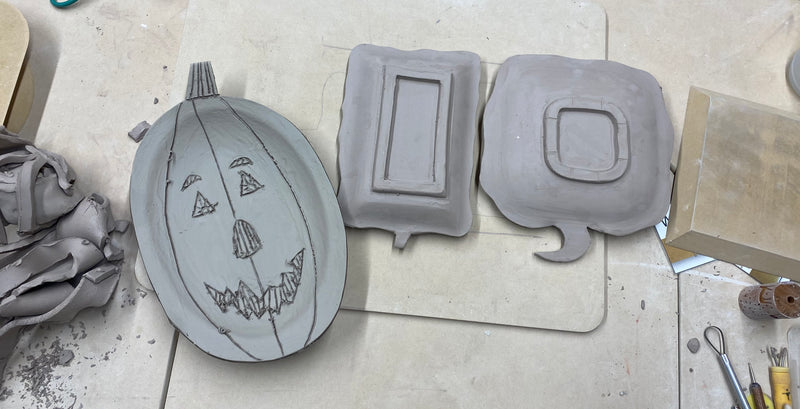

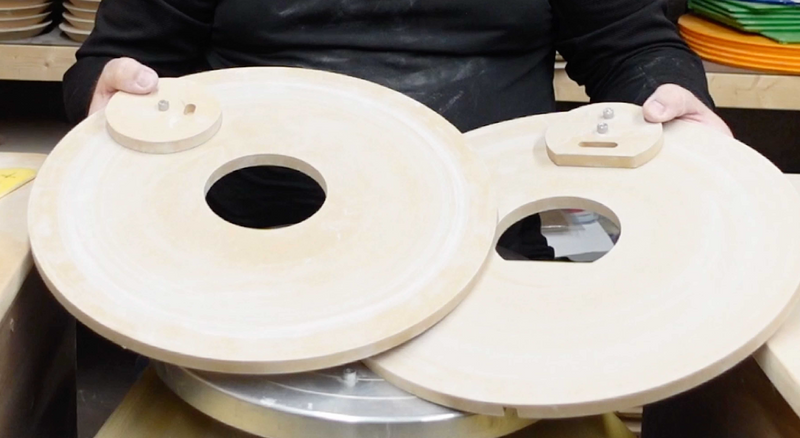

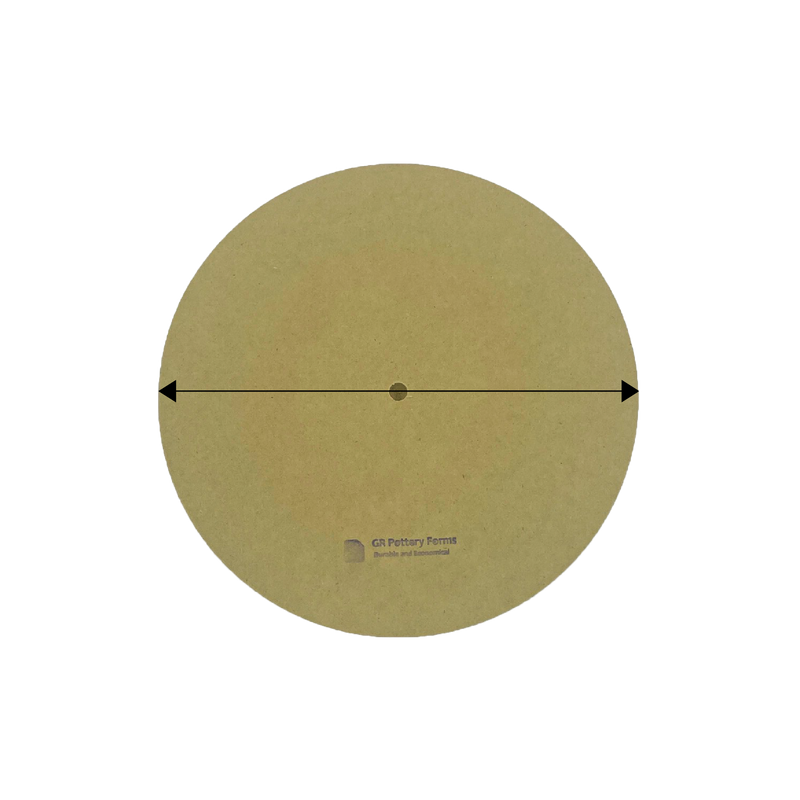

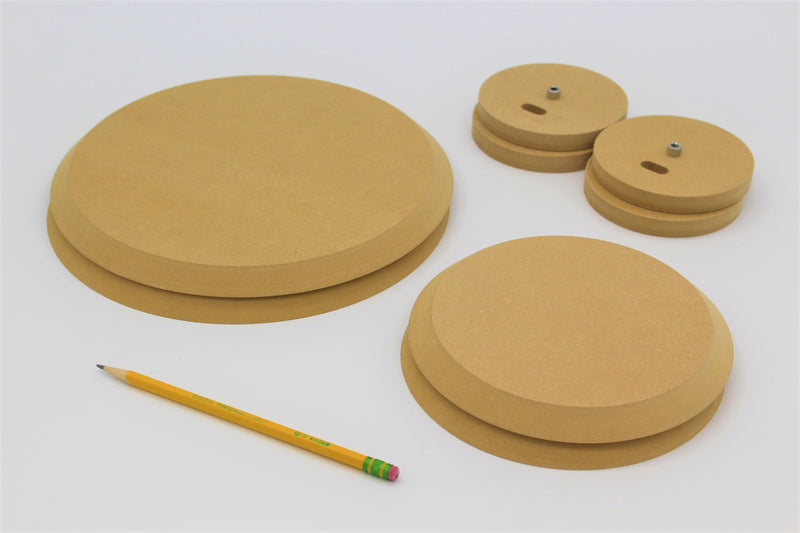

2. Drape the Compressed Side Over the Form

Once the slab is compressed, carefully drape it over your Form, ensuring that the compressed side is facing down. This is the side that will take on the shape of the Form beneath it, providing a smooth surface for the final piece.

3. Gently Push Clay Up to the Form, Adding Pressure as You Go

Using your hands, gently push the clay upward to meet the Form, starting from the base and working your way up. Apply even pressure as you move along to avoid wrinkles or cracks in the clay and help eliminate any trapped air pockets between the clay and the Form. As you do this, the clay will begin to take on the shape of the Form.

4. Use a Rib to Compress Clay to the Forms

Once the clay is roughly shaped, use a Yellow #5 Mudtools Rib to compress it onto the Form more firmly. This compression ensures that the clay adheres to the Form. The surface will become smooth and even.

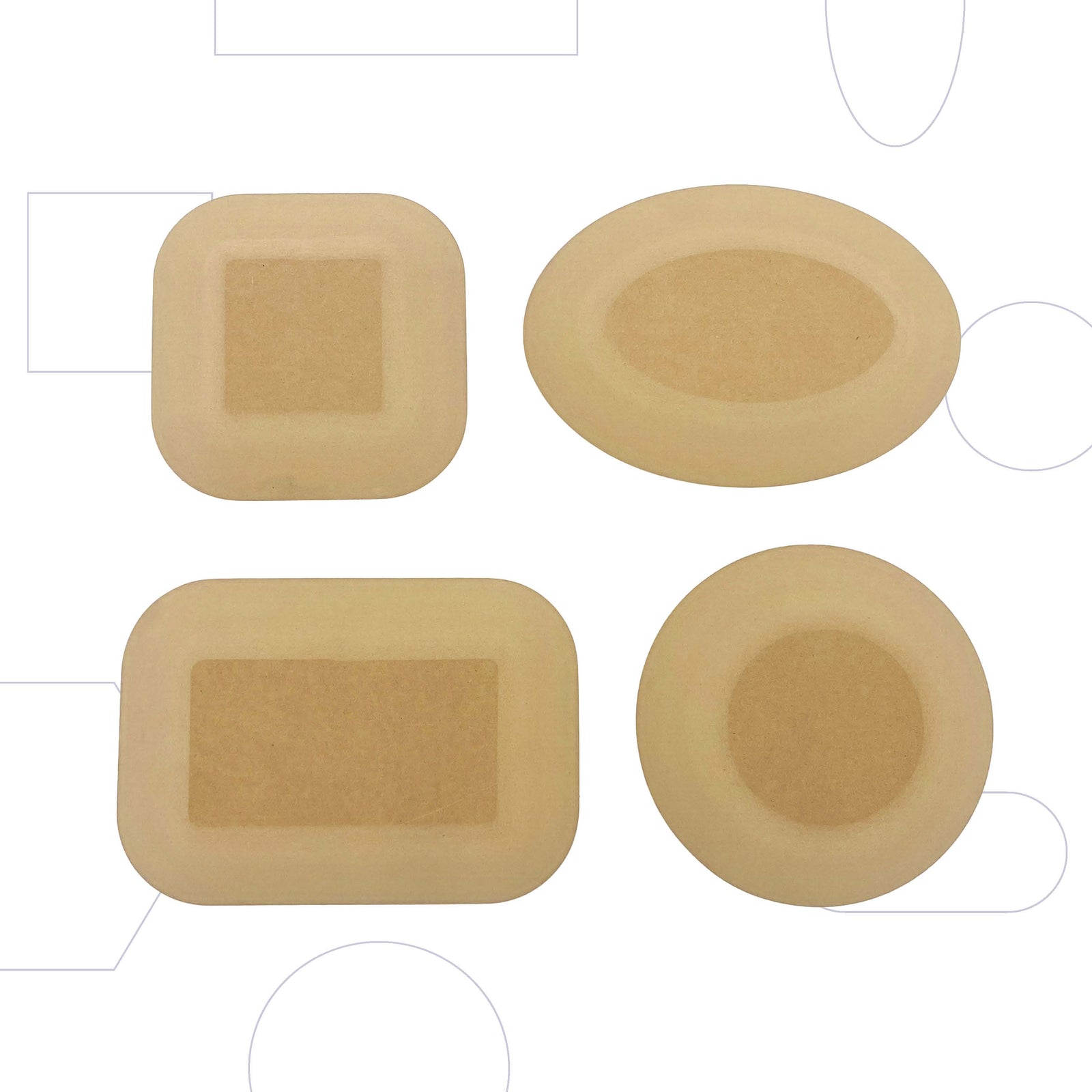

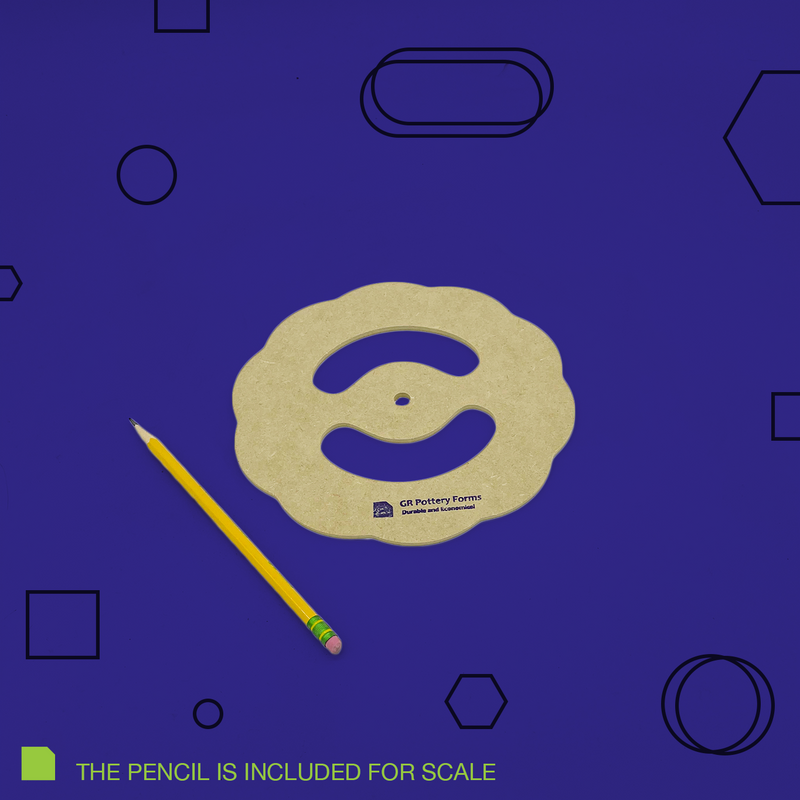

5. Use the Foot Maker Tool to Make Strips of Clay

Next, you’ll need to make the foot for your piece. Use the Foot Maker Tool to cut even strips of clay. These will form the base of your dish or container, providing stability and a finished look.

6. Use a Sue Tool to Measure the Placement of the Foot

Now, use a Sue Tool to measure where you’d like to place the foot of the plate. Mark a light line around the base where the foot will be attached.

7. Place Foot and Press Down, Using a Modeling Tool to Help Connect the Edges

Press the clay strips onto the bottom of the tray, positioning them evenly around the base. Use a modeling tool to help connect the edges of the foot to the tray, blending them together to create a seamless transition.

8. Trim the Edge

Once the foot is ready, it’s time to trim the rim of your piece. Use a Loonie Clay Knife or a wire tool like the Dirty Girls Slingshot or harp wire to trim the top edge of the slab to your desired shape and height.

9. Clean Up the Rim with a Sponge

After trimming, use a damp sponge to gently smooth and clean up the rim. This will help remove any rough edges or tool marks.

10. Set Aside to Dry for 4-6 Hours or Until Leather-Hard

Now that your piece is shaped and the rim is clean, set it aside to dry in a draft-free area for about 4-6 hours. The goal is to let the piece dry to a leather-hard state, which means the clay is firm but still has a bit of moisture, making it easier to handle without losing shape.

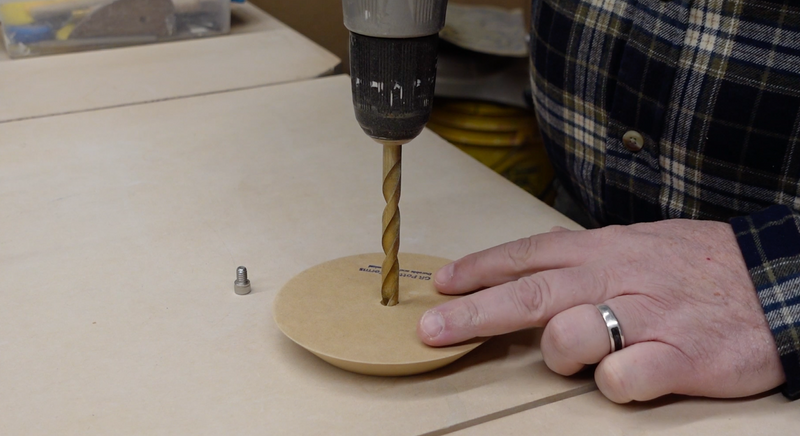

11. Remove the Form and Clean Up the Rim

When the clay has reached leather-hard consistency, carefully remove the formed clay from the mold. If the clay is still a bit soft, wait a bit longer for it to firm up. Once the Form is removed, you may need to clean up the rim again. Use a Notched Rib or rasp to refine the edge, removing any tool marks or unevenness.

12. Let the Piece Dry Completely

Set your piece aside to finish drying until all moisture has been eliminated. If your piece has a flat rim all around, it’s best to let it finish drying upside down to avoid warping. Be sure the piece is bone-dry before proceeding to the next step.

13. Bisque Fire the Piece

Once your piece is completely dry, it’s ready for bisque firing. Place it in the kiln and fire it according to the temperature specifications for your clay body. The bisque firing prepares the piece for glazing, removing any residual moisture and hardening the clay.

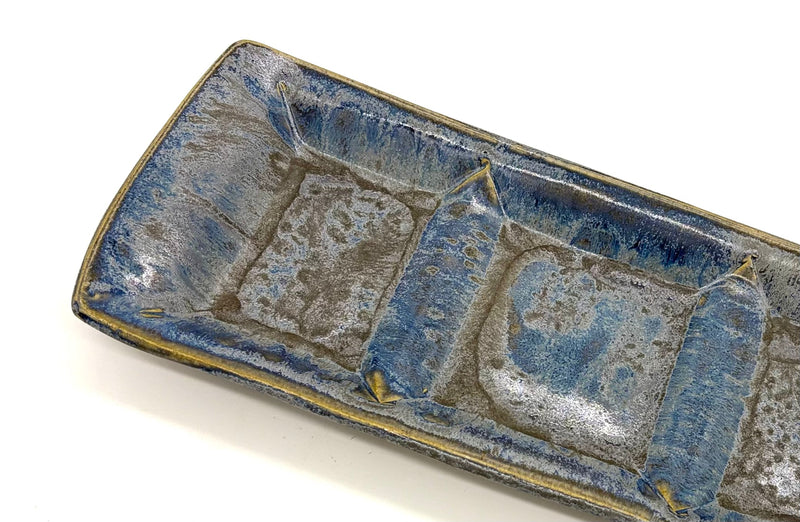

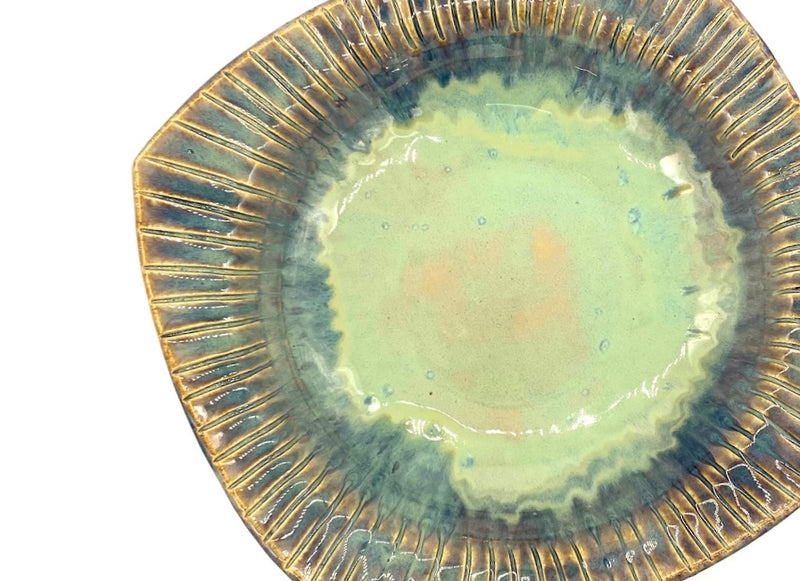

14. Dip in Clear Glaze and Refire

After the bisque firing is complete and the piece has cooled, dip it in a clear glaze to give it a glossy, finished look. Once glazed, fire the piece again according to the glaze’s recommended firing temperature. This final firing will set the glaze and complete your piece.

We hope these steps were helpful on how to create functional pieces with our RD2 Starter Set. Here is a tutorial video that goes through the above steps:

Tools used in this blog:

RD2 Starter Set - https://grpotteryforms.com/products/rd2-starter-pack?_pos=1&_sid=418327578&_ss=r

Medium Mudtools Rib - https://grpotteryforms.com/products/mudtools-rib-medium-1

Kemper Modeling Tool - https://grpotteryforms.com/products/tool-modeling-tool

Loonie Clay Knife - https://grpotteryforms.com/products/loonie-clay-knife

Stanley Surform Rasp - https://grpotteryforms.com/products/tool-stanley-surform

Sue Tool - https://grpotteryforms.com/products/tool-sue-tool-blue

Foot Maker Tool - https://grpotteryforms.com/products/tool-foot-maker

Trimming Tool - https://grpotteryforms.com/products/trimming-tool-flat-round